Blogs

Blogs

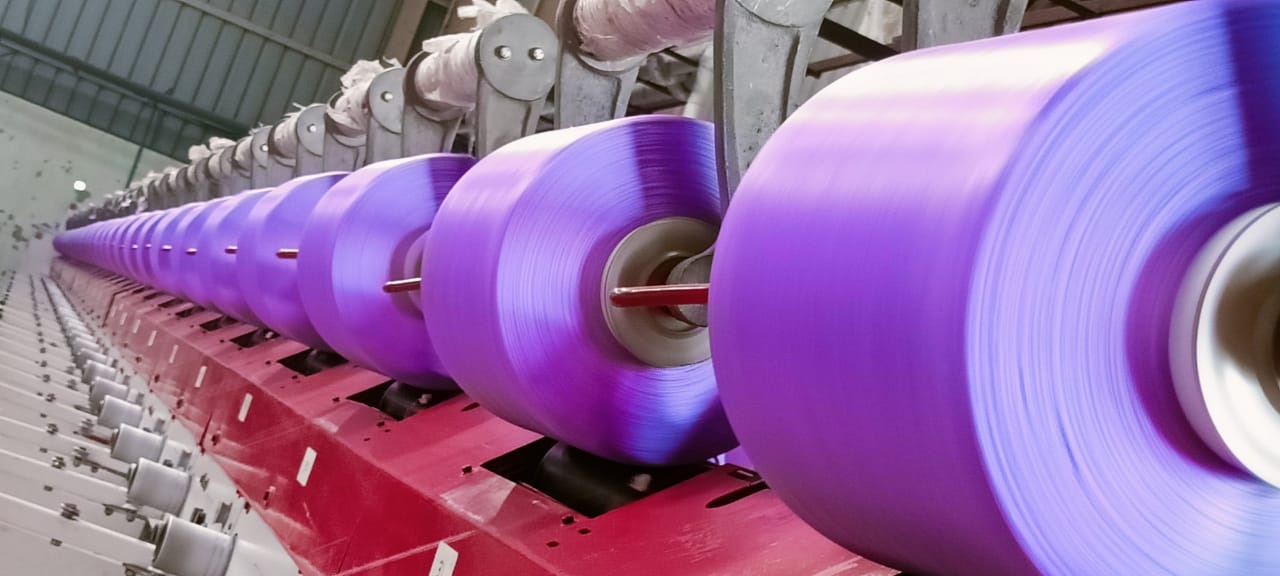

At Laxmi Filaments, we take pride in being a leading PP multifilament yarn Manufacturer in India. With state-of-the-art technology and a dedicated team of experts, we strive to deliver excellence in every strand we produce.

Founded in 2018, we are a dynamic and forward-thinking company driven by a passion for excellence and innovation. With a vision to redefine industry standards, we embarked on a journey to establish ourselves as a prominent player in India

FDY Yarn

FDY (Fully Drawn Yarn): FDY stands for "Fully Drawn Yarn." It is a synthetic yarn made through a process where the polymer chips are melted and extruded into continuous filaments, which are then drawn or stretched to align the molecules and enhance the yarn's strength and properties. FDY yarns are known for their durability, smooth texture, and uniform diameter

The importance of PP multifilament yarn in filters lies in its ability to provide efficient filtration, chemical and moisture resistance, thermal stability, ease of processing, and cost-effectiveness. These properties make it a valuable material for manufacturing filters used in various industries, including air and water purification, industrial processes, healthcare, and more

In summary, the importance of PP multifilament yarn in geotextiles lies in its strength, durability, resistance to environmental factors, and versatility, which are essential characteristics for effective geotextile applications in construction, soil reinforcement, filtration, and erosion control projects

Congratulations to Team India for their remarkable achievement of winning 100 gold medals in the Asian Games! This is a testament to the hard work, dedication, and exceptional talent of our athletes. Their incredible performances have made the entire nation proud. Here's to many more victories and continued success in the world of sports! 🥇🇮🇳 #TeamIndia #AsianGames #GoldMedals

In the world of textiles, one innovation stands out for its exceptional strength and versatility – Polypropylene (PP) Multifilament Yarn

Polypropylene (PP) Multifilament Yarn: Weaving Excellence from Innovation

In the world of textiles, one material shines brightly for its versatility and strength—Polypropylene (PP) Multifilament Yarn. This remarkable yarn, crafted through a precise extrusion process, boasts a multitude of applications that span across industries. From reinforcing agricultural nets that support crop growth to providing the strength needed in heavy-duty packaging, PP Multifilament Yarn is the unsung hero. With its exceptional resistance to moisture and chemicals, it ensures longevity in demanding environments

The Science Behind Strength: Properties and Characteristics of PP Multifilament Yarn

Dive into the unique properties that make PP Multifilament Yarn stand out, including strength, durability, and resistance to moisture and chemicals

What is multi filament yarn?

A multifilament yarn is composed of a bundle of very thin, infinitely long threads. The threads are generally referred to as filaments. These yarns are generally spun on vertical machines with filaments extruded out of the spinnerets and air-cooled before getting wound onto spools.

- Regular/Standard: Basic yarn for general use in ropes, nets, and webbing.

- High Tenacity: Stronger yarn for heavy-duty applications like mooring lines and industrial fabrics.

- Low Shrinkage: Resists shrinking in high-temperature environments, used in automotive interiors and geotextiles.

- UV-Stabilized: Resistant to sun damage, ideal for outdoor products like furniture and awnings.

- Colored: Dyed yarn for aesthetics or visibility in safety ropes and fabrics.

- Flame-Retardant: Treated to reduce flammability, used in safety gear and automotive interiors.

- Antibacterial/Antimicrobial: Inhibits microorganism growth, common in healthcare textiles.

- Recycled: Made from recycled materials, contributing to sustainability.

- Soft: Engineered for comfort in clothing and textiles.

Each type serves specific purposes based on strength, appearance, durability, and other factors.

India's pursuit of space exploration reaches a remarkable milestone with the impending Chandrayaan-3 Mission, poised to achieve a soft landing on the lunar surface. This achievement marks a significant step forward for Indian Science, Engineering, Technology, and Industry, symbolising our nation's progress in space exploration.

This eagerly anticipated event will be broadcasted live on August 23, 2023, starting from 17:20 Hrs. IST. The live coverage will be available via multiple platforms, including the ISRO Website , YouTube, ISRO's Facebook page , and DD National TV channel.

Click link: https://www.youtube.com/watch?v=DLA_64yz8Ss

Introduction of Multifilament Yarn: The concept of multifilament yarn involves combining multiple filaments to create a stronger, more durable yarn. This technique was adopted in the textile industry to enhance the properties of synthetic fibers like polypropylene.

Evolution of Manufacturing Techniques: As the demand for strong and versatile fibers grew, manufacturers focused on refining the manufacturing processes of polypropylene multifilament yarn. Techniques such as melt spinning and filament drawing were developed to create finer, stronger filaments.

Discovery of Polypropylene: Polypropylene, the polymer used to make PP multifilament yarn, was first synthesized in the mid-1950s by J. Paul Hogan and Robert L. Banks of Phillips Petroleum Company. The discovery marked the beginning of a new era in polymer chemistry.

Early Years and Application Exploration: In the following years, researchers and engineers explored the potential applications of polypropylene. It was found to be an excellent material due to its lightweight, chemical resistance, and moisture resistance properties. It quickly gained popularity in various industries.

PP (Polypropylene) multifilament yarn is a type of synthetic yarn made from multiple continuous filaments of polypropylene fibers.

At Laxmi Filaments, we take pride in being a leading producer of high-quality PP multifilament yarn. With state-of-the-art technology and a dedicated team of experts, we strive to deliver excellence in every strand we produce.

PP webbing is a type of woven fabric made from polypropylene (PP) fibers.

At Laxmi Filaments, we take pride in being a leading producer of high-quality PP multifilament yarn. With state-of-the-art technology and a dedicated team of experts, we strive to deliver excellence in every strand we produce.

PP (Polypropylene) bag closing yarn is a specific type of bag closing thread made from polypropylene fibers.

At Laxmi Filaments, we take pride in being a leading producer of high-quality PP multifilament yarn. With state-of-the-art technology and a dedicated team of experts, we strive to deliver excellence in every strand we produce.